Fabrication of microscopic photonic devices and circuits with ultrahigh precision and ultralow loss is of great interest due to their potential applications in optical processing, quantum computing, microwave photonics, optical metrology, and advanced sensing. Surface nanoscale axial photonics (SNAP) is a new fabrication platform that allows us to fabricate photonic structures with an unprecedented subangstrom precision and ultralow loss. SNAP structures are usually fabricated by CO2 laser or UV laser exposure, but the minimum characteristic length of the introduced structure is relatively large for CO2 laser, while the requirement of photosensitivity of fiber restricts the applications of UV laser exposure.

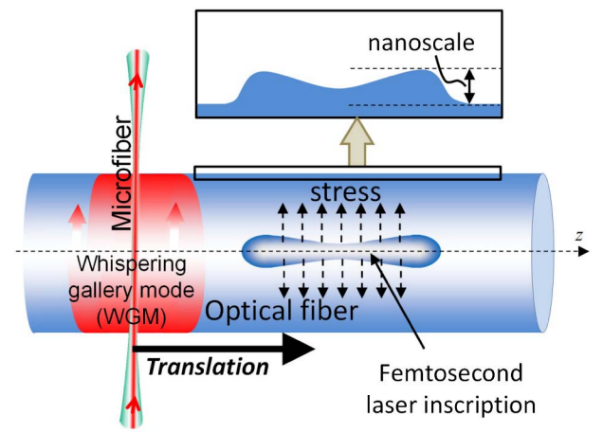

Femtosecond laser inscription is a powerful tool that has been successfully employed to fabricate in-fiber devices.To solved the problems of other fabrication methods mentioned above, Prof Xuewen Shu and PhD students Fangcheng Shen from Wuhan National Laboratory, together with Prof. Misha SumetskyandProf. Lin Zhang from Aston university, proposed and demonstrated the fabrication of surface nanoscale axial photonics structures with a femtosecond laser, femtosecond laser inscription introduced along the fiber axis pressurizes the fiber and causes nanoscale effective radius variation, through which the propagation of whispering gallery mode (WGM) circulating around the fiber surface can be controlled.

On June 13,2016,this work “Fabrication of surface nanoscale axial photonics structures with a femtosecond laser” was published onOptics Letters(vol. 41, no. 12, pp. 2795-2798, 2016). This work is partly supported by the Director Fund of Wuhan National Laboratory for Optoelectronics.

Fig. 2:Illustration of the SNAP structure caused by the stress introduced by a femtosecond laser inscription inside the fiber.

Fig. 2: Surface plots of resonant transmission spectra measured with 2 μm steps along the fiber