Long-period gratings (LPGs) serve as components in optical fiber sensors, filters, and fiber lasers. Most LPGs are fabricated with CO2or excimer lasers. Most fabrication methods attempt to induce changes in the period of the refractive index along the axis of the fiber. Another way to fabricated LPGs entails heating the fiber along the z-axis while the fiber undergoes rotation.Because multicore fibers (MCF) have more complex structures than single-core fibers, they yield more complex mode distributions.In this study, we developed a technology combining an LPG with an MCF and fabricated a new LPG-on-MCF structure.Many researchers have investigated helical structures in the cladding of fibers to couple different modes at some particular wavelength. There is little attention paid on the helical structure in the core of fibers. In this study, we designed a LPG with a helical structure on a special designed single mode MCF.

Quite recently, Doc.Xiang shen, from Fiber Laser Technology Group (FLTG) Wuhan National Laboratory for Optoelectronics, exploredahelical long-period grating manufactured with a CO2 laser on multicore fiber under the guidance of Prof. Jinyan Li, Luyun Yang,Nengli Dai. The MCF we used behaves as a kind of single mode fiber. The nineteen cores of MCF are distributed hexagonally which make the helical structure only exist in core area after heating and twisting. There are several strong couplings between the core and cladding modes at different wavelengths when the grating pitch was 900 µm. The extinction ratio of the main coupling reached 20 dB at 1550 nm. We have investigated the sensor characteristics of the HLPG. It is found that the grating presents clear sensitivity to refractive-index while exhibiting smaller cross-sensitivity to environmental temperature than conventional long-period gratings. The HLPG also shows great potential as a twist sensor, which has a sensitivity up to 0.198 nm/(rad/m) and can apply for measuring twist directions.

This work entitled with “Helical long-period grating manufactured with a CO2 laser on multicore fiber” has been published inOptics Express(Optics Express,25(9): 10405-10412(2017)),in the optical society of America (OSA). This work was financially supported by the National Natural Science Foundation of China (Grant No. 61575075, 61535009).

Fig. 1. Fabrication of an HLPG. (a) A cross-sectional view of a 19-core fiber. (b) The process of fabricating an HLPG. (c) A schematic illustration of a portion of the fabricated HLPG.

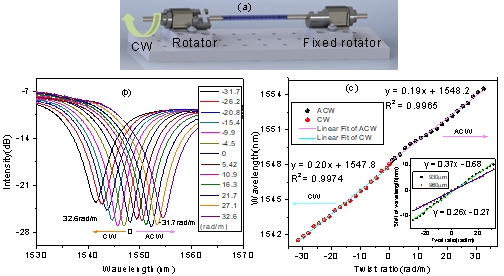

Fig. 5. Twist sensitivity of HLPG. (a) Platform for the twist test. (b) Changes in spectrum under different twist angles. (c) Linearity of the central wavelength increases with increases in dip twist ratio.