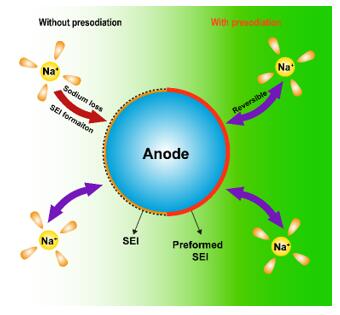

With the continuous consumption of fossil energy and the growing problem of environmental pollution, it is extremely urgent to develop green and sustainable energy sources. Sodium-ion battery (SIB) as one of the promising choices for grid-scale energy storage systems owing to the abundant reserves of sodium element in the crust and its low cost. Carbon-based materials are considered to be one of the most promising anodes in SIBs for industrialization in the near term benefiting from their excellent conductivity, good structural stability, and notable corrosion resistance etc. However, one serious problem for carbon anodes is their low initial Columbic efficiency (ICE usually less than 80%), which reduces the overall energy density of SIBs. Therefore, increasing the first-cycle Coulombic efficiency of the negative electrode to reduce the loss of active sodium ions is very important to address the initial sodium loss and increase the energy density of the full cell. Several presodiation techniques have been developed so far to offset the initial sodium loss in SIBs, including electrochemical presodiation, sacrificial sodium sources presodiation and sodium metal powders presodiation. However, the processes of these presodiation techniques are complicated, and might cause safety concerns. Thus, it is highly desirable but challenging to explore a simple and high-efficiency presodiation approach in consideration of the practical application in battery industry.

Prof. Yongming Sun and co-workers reported the rational design of a simple and novel electrode-level presodiation approach, which not only preforms a SEI layer on the surface of the hard carbon anode surface but also prestores certain amount of active sodium ions into the carbon anode. The presodiation process is conducted by spraying a designed presodiation solution onto a hard carbon electrode with a subsequent drying process before battery assembly. the presodiation degree of the anode can be well controlled through adjusting the dosage of the presodiation solution(ICE 67-96%). a Na0.9[Cu0.22Fe0.30Mn0.48]O2||carbon full cell with a presodiated carbon anode showed dramatically increase in capacity and energy density in comparison to the Na0.9[Cu0.22Fe0.30Mn0.48]O2||carbon full cell with a pristine carbon anode(240 vs. 141 Wh kg −1). Moreover, this simple presodiation approach was generalized to other anode materials for SIBs with large first-cycle irreversible capacity loss, such as metal oxides-based and alloy-based anodes (e.g., TiO2 and Sn). Also, this approach was applied to prelithiate the anode of lithium-ion batteries.

The relative work has been published in Advanced Functional Materials (DOI:10.1002/adfm.201903795) with the title of “A Simple Electrode-Level Chemical Presodiation Route by Solution Spraying to Improve the Energy Density of Sodium-Ion Batteries”. The first author is Dr. Xiaoxiao Liu and Ph.D student Yuchen Tan from Huazhong University of Science and Technology. The corresponding authors are prof. Yongming Sun and prof. Jun Lu.

Original link:https://onlinelibrary.wiley.com/doi/full/10.1002/adfm.201903795