Structural wrinkles in nature have been widely imitated to enhance the surface functionalities of objects, especially three-dimensional (3D) architectured wrinkles, holding promise for emerging applications in mechanical, electrical, and biological processes. In the pursuit of achieving 3D wrinkled structures, substantial efforts have been devoted to investigating biological wrinkles and bionic wrinkling construction on nonplanar substrates. Wrinkling patterns on curved substrates, such as spheres, cylinders, and tubes, have been fabricated by constructing core-shell systems with mismatch modulus and then by triggering surface instability under external stimuli. However, these methods can only achieve an intrinsic wrinkling pattern that is strongly constrained by the geometry of the substrate, which cannot be applied to arbitrary architectures.

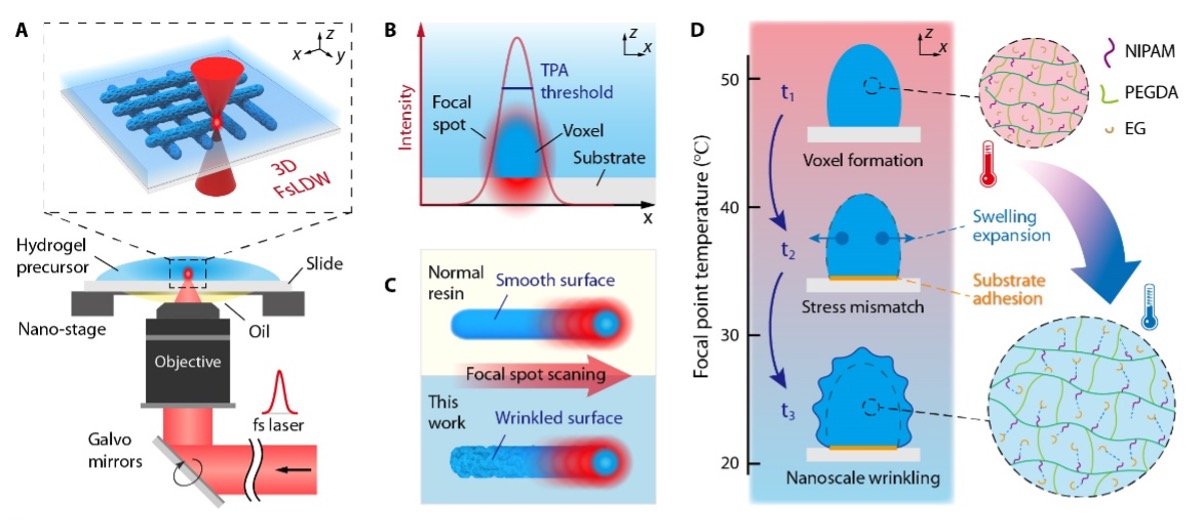

Figure 1. Schematic illustration of the strategy for nanoscale wrinkling.

Professor Wei Xiong’s group proposed a bottom-up laser direct assembly strategy to fabricate multidimensional nano-wrinkled architectures in a single-material-one-step process. For the first time, the template-free 3D fabrication of wrinkled architectures is realized. This technique features the coupling of the laser-induced thermal responsiveness of hydrogels with a nano-printing process, which guides the self-organization of nanowrinkles and the multidimensional structuring. During the entire wrinkling process, only one step of femtosecond laser direct writing in a single hydrogel precursor material is involved.

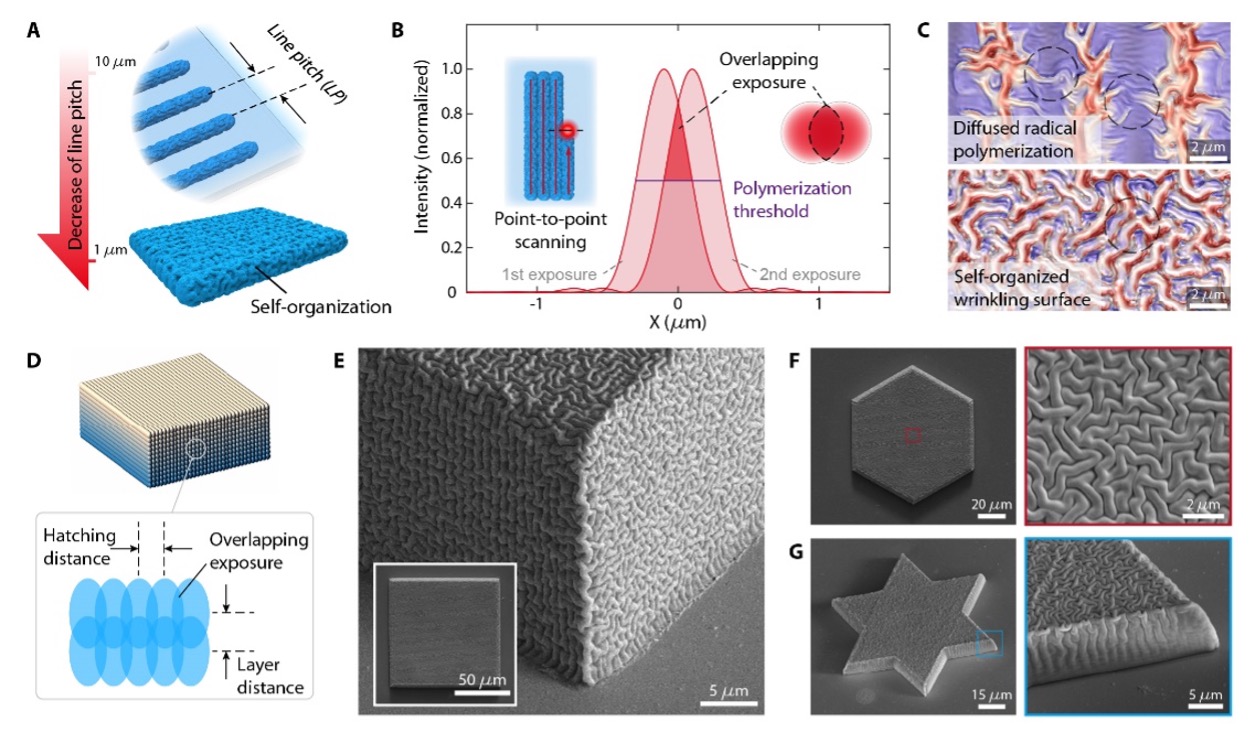

Figure 2. Self-organization of wrinkle structures.

This bottom-up fabrication demonstrates a flexible ability to construct wrinkle patterns into 1D, 2D, and 3D hierarchical architectures. Furthermore, the research group realized the precise control and tunability of wrinkle pattern formation and observed an interesting yet abnormal micromechanical behavior of the as-fabricated 3D wrinkled microarchitecture. Moreover, the precise control of wrinkle morphology with an optimal wavelength of 40 nm and the regulation of the dynamic transformation of wrinkled cellular microstructures via interfacial stress mismatch engineering has been achieved. This study provides a universal protocol for constructing nearly arbitrary nano-wrinkled architectures and facilitates a new paradigm in nanostructure manufacturing.

Figure 3. Printing of complex nano-wrinkled 2D and 3D microarchitectures.

Related work has been published in Science Advances, with the title 3D Printing of Nano-wrinkled Architectures via Laser Direct Assembly on August 10, 2022 (https://www.science.org/doi/10.1126/sciadv.abn9942). The first unit for this research is the Wuhan National Laboratory for Optoelectronics, Huazhong University of Science and Technology, and it has been funded by the National Key Research and Development Program of China, Innovation project of Optics Valley Laboratory and China Postdoctoral Science Foundation.