The Antiresonant reflectingfibersinclude a series of fibers such as Bragg fiber, photonic crystal fiber, Kagomé fiber, and negative-curvature hollow fiber. In the fiber,the high refractive index layer is regarded as aFabry-Perot cavity. The light goes out of thehigh refractive index layer when the wavelengthis close to the resonant wavelength. However,when the propagating wavelength is far awayfrom the resonant wavelength, the light shouldbe reflected back, resulting in good confinement.Therefore,the matching conditionof wavelengthdeterminedthe band edges of high-loss and lowloss regions.The Antiresonant reflectingfibershasbeen identified to play an important role in near-infrared and THz optical signal transmission.Althoughhollow-core fiber (HCF)coated with functional material films have been reportedfor biosensing, magnetic field sensing and humidity sensing,direct use of uncoated HCFs forsensing has not been reported.The coating process increases the complexity of the device, reducing the stability and reliability of the device.

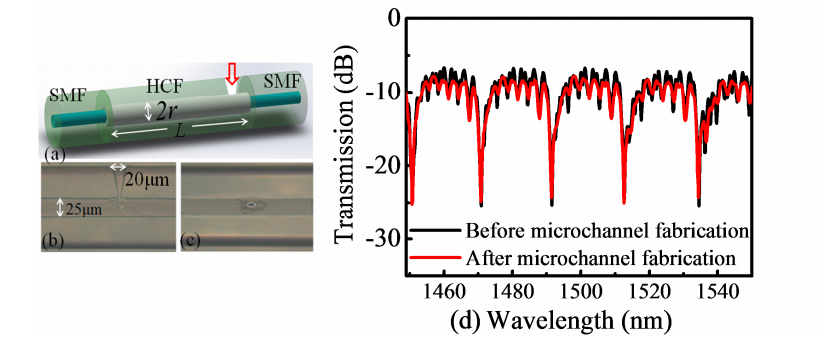

The ultrafast optics group led by Prof. Peixiang Lupresentsa gas pressure sensor based on an antiresonant reflecting guidance (ARRG)mechanism in an HCF.The pressure sensor is comprisedof an HCF section with an open microchannel fabricated through the ring cladding of the HCF by fslaser micromachining. Here, the HCF serves as an antiresonant reflecting waveguide, and themicrochannel allows for an air-core pressure equivalent to that of the external pressure. The ARRGbased sensor exhibits sharp periodic losses in the transmission spectrum, and the resonant losses exhibita wavelength shift with a linear sensitivity of 3.59 nm/MPa and a low temperature cross-sensitivity of7.5 kPa/°C. Theoretical analyses indicate that the pressure sensitivities for the ARRG sensors aremainly results from the refractive index change of air within the hollow-core. Moreover, theproposed device exhibits the advantage of simplicity, stability and high sensitivity.

This work is published on Opt. Express Opt. Express Vol. 24, No. 24, 27890(2016). This work was supported by the National Natural Science Foundation of China under Grants No. 61138006.

Fig.(a) Pictorial view of the designed pressure sensor based on an antiresonant reflecting guidance (ARRG)mechanism in a hollow-core fiber (HCF). (b) Side-view and (c) top-view optical microscopy images of themicrochannel created by femtosecond laser micromachining. (d) Transmission spectra of the ARRG-based pressuresensor with an HCF length of 5 mm before and after microchannel fabrication.