On December 17, Prof. Jingyu Zhang, from Wuhan National Laboratory for Optoelectronics (WNLO), Huazhong University of Science and Technology (HUST), led a team to publish the new research advances in Advanced Optical Materials. The paper is entitled “Near-Field Mediated 40 nm In-Volume Glass Fabrication by Femtosecond Laser”.

Nanofabrication is a cornerstone of many prominent nanoscale applications, such as 3D printing, nanomechanical device, nanophotonics device, and data storage. Prevailing nanofabrication approaches are mainly based on charged particle lithography, which requires the direct contact of focused particles and processed materials, thus confines the fabrication to surface modification. Similarly, non-contact techniques such as tip-enhanced nanolithography, near-field mediated surface nanoscribing, and laser-assisted etching, require the presence of an air-substrate interface, prohibiting their applications in bulk materials. Due to the lack of a proper approach enabling nanofabrication in bulk materials, volume nanostructures with specifically designed geometries have been rarely studied.The currently widely used femtosecond laser processing technology has the advantages of reducing heat-affected area and achieving high accuracy, but the internal processing accuracy of the bulk material still stays at the micron level.

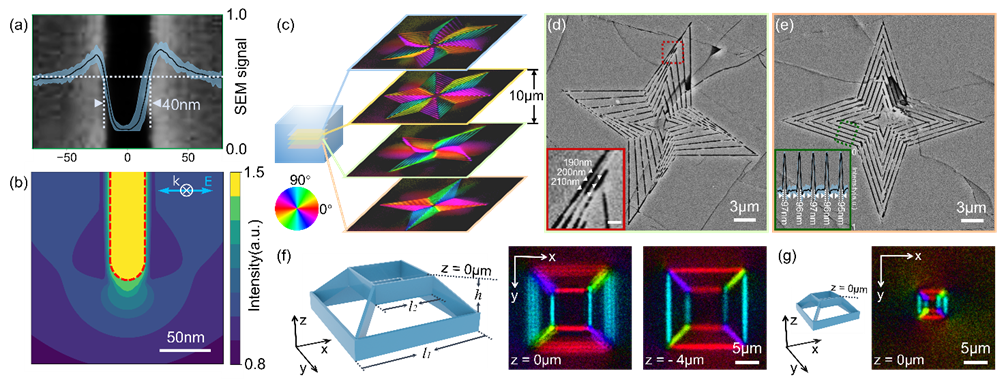

In response to this technical problem, Prof. Zhang’s research team has induced a single nanoslit (SNS) structure in the fused silica glass material by focusing linearly polarized femtosecond laser pulses. The structurewitha width down to 40 nm or even 20 nm is much smaller than the diffraction limit of laser focusing, and the SNS formation mechanism is explained in terms of a local electric field redistribution attributed to interaction of vector light field with structure. Asproof-of-concept, 3D nanostructures and birefringence voxels, constructed from SNSs, are fabricated, demonstrating the great potential of SNS structures for nanofabrication and multidimensional optical data storage applications.

Generally, the linearly polarized femtosecond laser pulses focused by the objective lens can induce a continuous birefringent structure inside fused silica glass. In this work, the team finds strength of birefringence exhibits periodic variation along the laser scanning path that depends on the laser beam polarization when studying near-threshold processing behavior. And a SNS structure with a width down to 40 nm is formed when the laser polarization direction is perpendicular to the scanning direction. They believe that a single optical-scale quasi-isotropic nanovoid with a diameter of over 100 nm is induced at the initial stage of SNS formation. With subsequent laser pulses, the nanovoid moves upward and sticks onto the ceiling of the upper focal region, where the surrounding glass possesses high viscosity. Simultaneously, the nanovoid elongates perpendicular to the polarization orientation due to the near-field enhancement. During the ascent and elongation process, such quasi-isotropic nanovoid evolves into a precursor of SNS with a high-aspect-ratio along the longitudinal direction. According to calculations, the material in the SNS is similar to the structure in the nanogratings, which is filled with nanoporous glass structure. The formation mechanism of SNS can be further extended to the formation mechanism of multi-plane nanogratings.

In the line spacing experiment, it is found that the experimental spacing of two SNSs is mismatched with the scanning spacing of laser path. When the scanning spacing is less than 150 nm, the pre-existing SNS will be repeatedly modified during the second laser scanning, and no trace of a second SNS is found. These experimental phenomena and simulation further confirm that the formation of the SNS structure is resulted from the redistribution of the light field caused by the near-field enhancement effect. In addition, a more interesting phenomenon is that periodically curved and bifurcated SNSs with 30 nm line-width can be observed when the polarization direction is in the range of 60° to 120° (excluding 90°) whereas under a high numerical aperture (1.3 NA). This is in stark contrast to what was observed in previous experiments, where multi-plane nanogratings is always oriented perpendicular to the electric field of light. This indicates that both the near-field enhancement effect and the initial distribution of the focused spot will affect the redistribution of the light field, which plays a decisive role in the growth direction of the SNS. The application of three-dimensional nanofabrication inside bulk materials and high density five-dimensional optical data storage are implemented by the polarization control characteristics of a SNS structure. In addition, the potential applications of this 3D nanofabrication approach in bulk materials are broad, including nanofludics, metastructures, nanophotonics, and nanomechanics.

This work is supported by Creative Research Group Project of NSFC (Grant Nos. 61821003), Innovation Fund Project of WNLO, and Program for HUST Academic Frontier Youth Team. PhD student Zhi Yan is the first author, and Professor Jingyu Zhang is the corresponding author. Other collaborators include PhD student Jichao Gao, and Dr. Martynas Beresna from University of Southampton, UK.

FIG.1 (a) Scanning electron microscopy image of 40 nm single nanoslit; (b) Contour map of the FDTD-simulatedfield intensity distribution of a focused light (0.7 NA) irradiating on a slit-like inhomogeneity; (c) Images of the slow axis orientation of fabricated nanopatterns in four adjacent layers; (d), (e) Corresponding SEM images of the 3rd and 4th layer in (c); (f), (g) Schematic diagrams and corresponding slow-axis orientation images of truncated pyramid structures of different sizes at different imaging planes.

Written by: Zhang Jingyu

Reviewed by: Dong Jianji, Gou Bingbing