As the ultimate anode of choice for lithium-based rechargeable batteries, lithium (Li) metal cannot be operated with regular electrode configuration and battery package above its melting temperature (180.5ºC) due to its liquid nature, which restricts its application in some special fields, such as grid, outer space and military applications.The complex battery configuration and high reactivity of liquid metallic Li cause high costs andsafety concerns.Therefore, it is of vital importance to explore Li metal electrode with goodthermal tolerance which can simplify the battery configuration for high-temperature Li metalbatteries and improve the thermal safety of regular Li metal batteries.

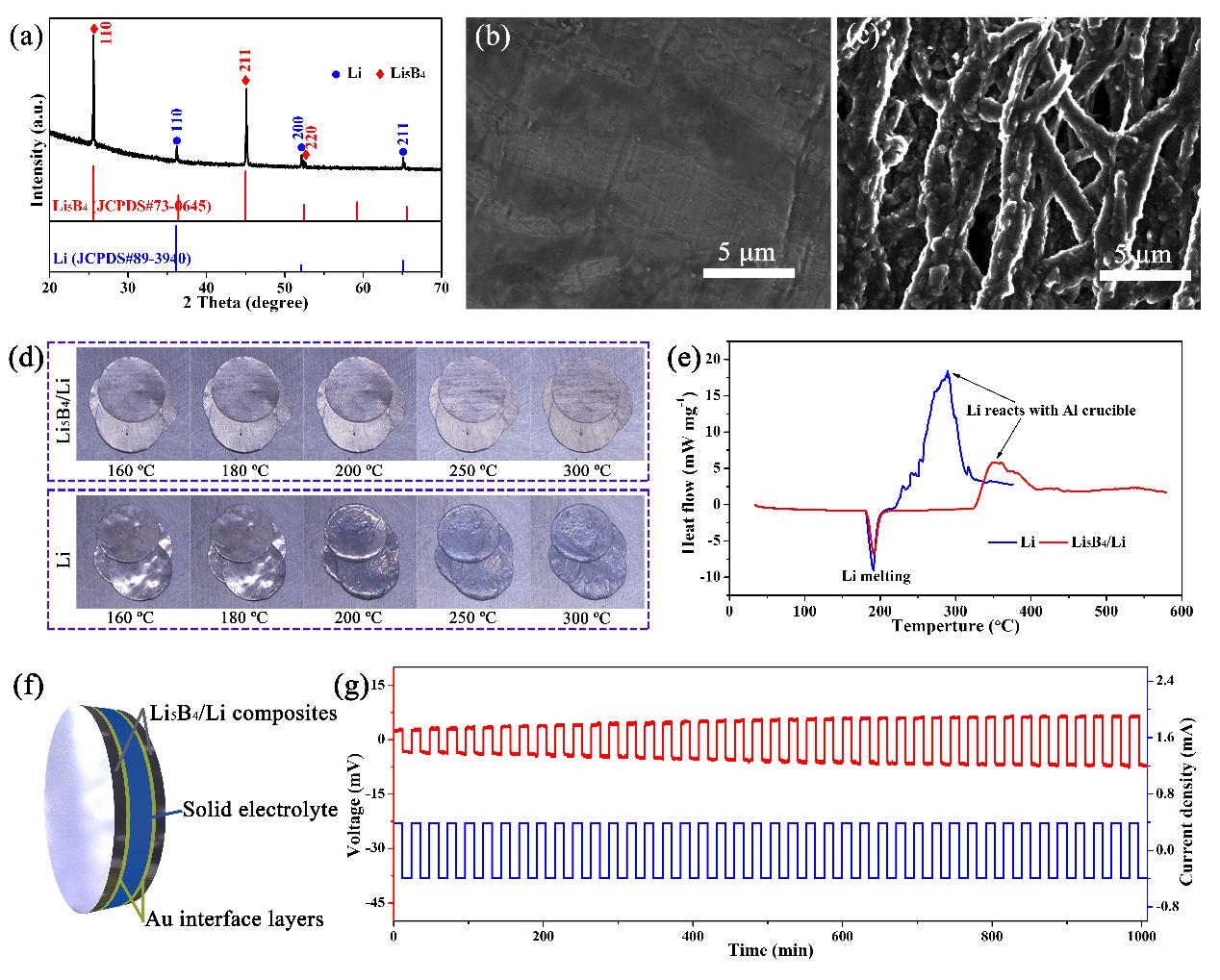

Yongming Sun’group and co-authors proposed that Constructing Li-based composite based on the 3D framework structure with thermal and mechanical stabilitytoreplace thepureLi, and took Li5B4/Li composite material as an example to verify the design idea successfully.As a demonstration of the Li5B4/Li composite electrode applied in high-temperature Li metal batteries, we fabricated a Li5B4/Li||Li5B4/Li symmetric cell using garnet-type Li6.5La3Zr0.5Ta1.5O12(LLZTO) solid electrolyte in a simple cell configuration and achieved stable electrochemical Li plating/stripping cycling with low overpotential and stable cycling at 200 ºC.The structure of Li5B4/Li can be described as metallic Li filledin the fibrillar Li5B4 framework that interconnects with each other.This unique structure offers multiple advantages for rechargeable high-temperature Li metal batteries:(1) the porous structure of Li5B4fibrillar framework with its lithiophilic surface can restricts the leakage of liquid metallic Li (with a high metallic Li content of 72%, the liquid metallic Li would not leak out of the composite electrode at 325ºC.) ; (2) Li5B4alloy possesses good thermal and mechanical stability, and it maintains its phase and structure about 1000ºC, (3) thedecomposition potential of Li5B4as high as 0.88 V (vs. Li+/Li), ensuring that the stable 3D framework of Li5B4alloy will be maintained over cycling of metallic Li; (4) high conductivity of Li-B alloy framework provides pathway for charge transport. The use of the Li5B4/Li composite electrode can avoid complex battery configuration that pure Li metal anode need, reduce the safety concerns caused by the flow of liquid metallic Li at high temperature, and thus show potentially practical application value.

Figure 1.Frontispiece inAdvanced Materials

Figure 2.(a) XRD pattern and (b) surface SEM image of the Li5B4/Li composite. (c) Surface SEM images of the Li5B4/Li composite after Li stripping.(d)Digital photos of the Li5B4/Li and pure Li disks at the 160, 180, 200, 250 and 300ºC, respectively. (e) DSC curves of the Li5B4/Li composite and pure Li. (f) Schematics for the construction of a Li5B4/Li||Li5B4/Li symmetric cell with LLZTO solid state electrolyte pellet and(g) its cycling voltage profiles at 200ºC with the current density of 0.5 mA cm–2 and areal capacity 0.1 mA h cm–2.

Related work has been published onAdvanced Materials(Adv. Mater., 2020,https://onlinelibrary.wiley.com/doi/full/10.1002/adma.202000952) On May 28, 2020, with the title of “A Lithium Metal Anode Surviving Battery Cycling above 200ºC". The first unit to complete this research is Wuhan National Laboratory for OptoelectronicsHuazhong University of Science and Technology, and it has been funded by National Key R&D Program of China (No. 2018YFB0905400) and National Natural Science Foundation of China (No. 51802105).